Viewing 2 posts - 1 through 2 (of 2 total) Lathe Machine Simulator and a Bonus.

#Lathe cnc simulator software#

Graphics software uses OpenGL 3.0 components. This topic has 1 reply, 1 voice, and was last updated 16 minutes ago by redthunder. The functionality of the simulator: preparation of texts of control programs of turning operations in the format of a standard G/M-code, checking control programs for syntax and technological errors, playing on the computer screen (or other computing device) three-dimensional graphic models of the main components of the lathe machine and metal-cutting tools to simulate the process of turning metal, the three-dimensional visualization of the process of forming parts during turning on the compiled control programs, visualization of toolpaths, implementation of interactive user interaction with the simulation model of technological equipment.

#Lathe cnc simulator verification#

A CNC Simulator That Allows Verification Inside CATIA. The FANUC CNC Simulator is based on the FANUC Series 0 i MODEL F platform and can be started up in either milling or turning configurations.

#Lathe cnc simulator full#

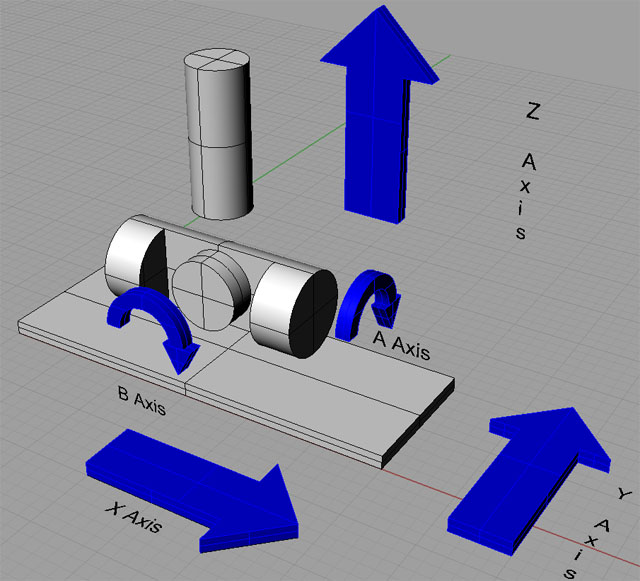

NC Viewer is the best free gcode editor for verifying CNC and 3D printer files. The FANUC CNC Simulator brings the world’s most popular CNC control right into the classroom, providing students with exposure to FANUC CNC controls without the need for a full machine. Material processing is performed on two axes in the horizontal plane.įield of application of the software product: educational process using computer technology: laboratory lessons of students in computer classes, distance learning, demonstration support of lecture material in the group of areas of training and specialties: Metallurgy, Engineering and Material Processing. G08 cnc code simulator Powerful online GCode Viewer to simulate GCode files. The basis of the three-dimensional simulation. with provision for final view in 3D using OpenGL. It simulates the path that the tool of a CNC lathe would take for a given program.

It runs on web browsers with support to WebGL 1 and html5, which means you are able to run on desktop computer, tablets and smartphones without any installation. The basis of the three-dimensional simulation model is a lathe machine with a classical arrangement of units, equipped with a CNC system, an eight-position turret, a three-jaw chuck, a tailstock, a coolant supply system and other machinery. A software simulator of a numerical control (CNC) lathe is an educational methodological development intended for basic familiarization of novice machine building specialists with the principles of programming parts turning operations using standard GM code (Fanuc System A). CNC Simulator is a Computer Numerical Control (CNC) lathe machine simulator. CNC web simulator is capable of generating tool path and also the final 3D workpiece for Lathe, Mill and 3D printer machines.

A software simulator of a numerical control (CNC) lathe is an educational methodological development intended for basic familiarization of novice machine building specialists with the principles of programming parts turning operations using standard G/M-code (Fanuc System A).

0 kommentar(er)

0 kommentar(er)